What Is the Ideal Hardness for B2B Wax Molds for Casting Jewelry?

Hardness represents a critical functional property in the creation of wax molds for casting jewelry. This characteristic, measured on the Shore A durometer scale, dictates a mold’s ability to release intricate patterns without sacrificing dimensional stability. For a specialized partner like Star Harvest, specifying the ideal hardness is a fundamental step in their jewelry mold making process, directly influencing the quality and efficiency of a production run.

Balancing Flexibility and Tear Strength

The primary consideration involves balancing flexibility with tear resistance. A mold that is too hard may crack or resist the release of a complex wax pattern, while one that is too soft can deform and lose fine details. In their jewelry mold making operations, Star Harvest typically utilizes compounds between Shore A 20 and 30 for a broad range of designs. This range provides sufficient firmness to maintain shape during wax injection while offering enough flexibility for clean pattern extraction.

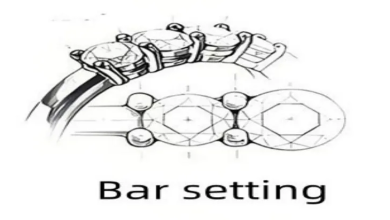

Accounting for Undercuts and Geometric Complexity

For designs featuring deep undercuts, sharp angles, or delicate projections, a softer mold is required to prevent damage during demolding. For such challenging projects, Star Harvest selects materials with a lower durometer to ensure gentle and safe release.These softer wax molds for casting jewelry can be carefully flexed and manipulated to release the pattern without tearing, preserving the integrity of fine details that are essential for high-quality castings.

Ensuring Durability Across Production Volumes

The anticipated production volume also guides hardness selection. For long runs requiring hundreds of wax patterns, a firmer mold provides greater longevity and resistance to deformation. Star Harvest recommends this for simpler designs where easy release is less of a concern than consistent performance over time. This approach ensures that the wax molds for casting jewelry remain dimensionally stable throughout the entire order.

The specification for wax mold hardness is therefore a technical decision, not a universal standard. Star Harvest’s methodology involves a calculated assessment of a design’s geometry and the production volume to determine the optimal durometer. This precise approach to jewelry mold making provides B2B clients with reliable, high-fidelity wax patterns, forming a dependable foundation for the subsequent stages of metal casting.