What Are the Critical Control Points in a Jewelry Manufacturing Facility?

Systematic monitoring at specific production stages determines the consistency and quality of the final output. Identifying and managing these critical control points allows a jewelry manufacturing facility to prevent defects rather than merely detecting them later. Star Harvest maintains a disciplined focus on several pivotal stages to ensure the integrity of its OEM jewelry production, integrating verification directly into the workflow.

Monitoring Raw Material Verification and Allocation

The first essential control point is the initial material intake. All incoming precious metals and gemstones are verified for purity, authenticity, and weight against supplier certificates. Star Harvest logs this data and assigns specific material lots to corresponding OEM jewelry production orders. This practice prevents material cross-contamination and ensures traceability from the very start of the jewelry manufacturing process, forming a reliable foundation for quality.

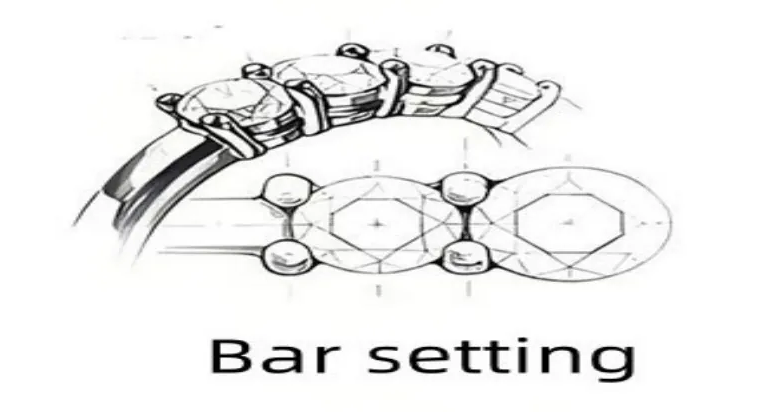

Regulating Wax Pattern and Mold Integrity Inspection

A second critical stage occurs after pattern creation. Each wax pattern or mold is inspected for dimensional accuracy, surface finish, and the absence of imperfections like bubbles or warping. Because any flaw in the pattern will be replicated and potentially magnified in the final metal cast, this step is a cost-effective control point for a jewelry manufacturing operation. Catching deviations here prevents wasted resources in subsequent metal casting and finishing stages for OEM jewelry.

Overseeing Pre-Shipment Dimensional and Functional Audit

The final control point is a comprehensive pre-shipment audit. This goes beyond a simple visual check to include precise dimensional verification against technical schematics and functional testing of clasps, hinges, and other moving parts. For Star Harvest, this last assessment confirms that the complete OEM jewelry batch meets all specified technical and functional requirements before it is released to the client, ensuring brand consistency and product performance.

The management of critical control points is a proactive strategy for quality assurance. Star Harvest’s focus on material verification, pattern inspection, and final auditing establishes a robust framework within its jewelry manufacturing operations. This systematic oversight provides brands with the assurance that their OEM jewelry is produced under a controlled, repeatable, and accountable system, directly supporting product reliability and market confidence.